BindEx Machinery Intelligent Postpress Technology Open House Successfully Ended

2023-11-01

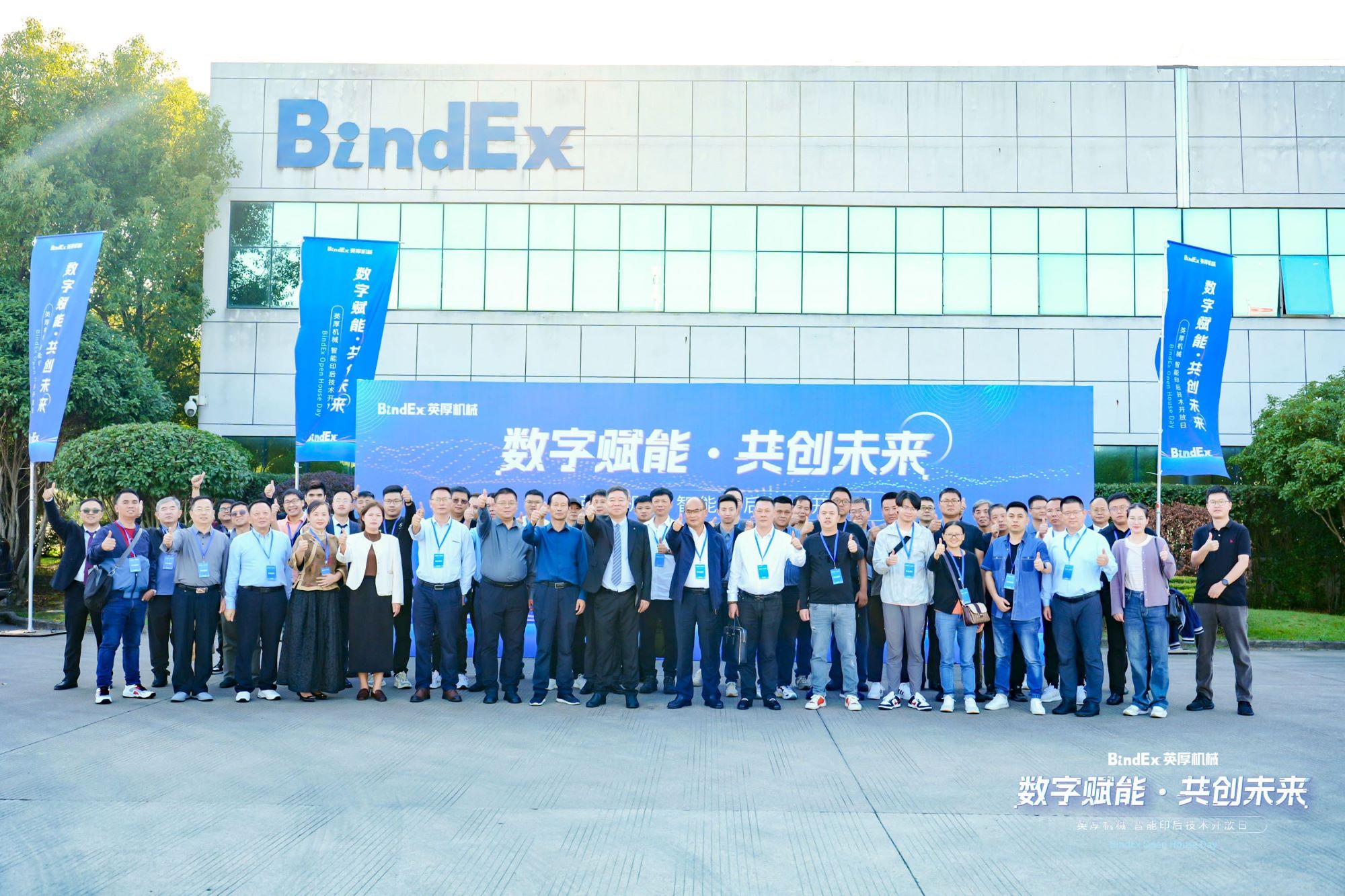

On October 30-31, 2023,BindEx Machinery hosted the "Digital Empowerment, Co-Creating the Future" Intelligent Post-Press Technology Open Day event in China. Over 600 industry experts from around the world gathered at BindEx Machinery to experience firsthand the digitized intelligent factory, providing a great learning platform for on-site visits and understanding of post-press-related technologies for printing enterprises.

Group photo of some visitors

Digital Empowerment Smart Factory Solutions Gaining Attention

At the beginning of the event, Ang Li, the General Manager of BindEx Machinery, delivered a speech on the theme of "Digitally Driving Intelligent Manufacturing." He expressed that as the level of digitization and intelligence in the printing industry continues to rise, printing enterprises have an increased understanding of digitization, and the digital transformation of enterprises is imminent. BindEx Machinery is closely following market demands and researching specialized solutions for intelligent printing factories. We are not only focusing on hardware research but also actively exploring and developing new technologies and products in the software field. We are committed to developing intelligent, efficient, and secure software products to break through data barriers, help managers understand real-time production progress, promptly address warning situations, and assist enterprises in intelligent and efficient production.

Ang Li, General Manager of BindEx Machinery

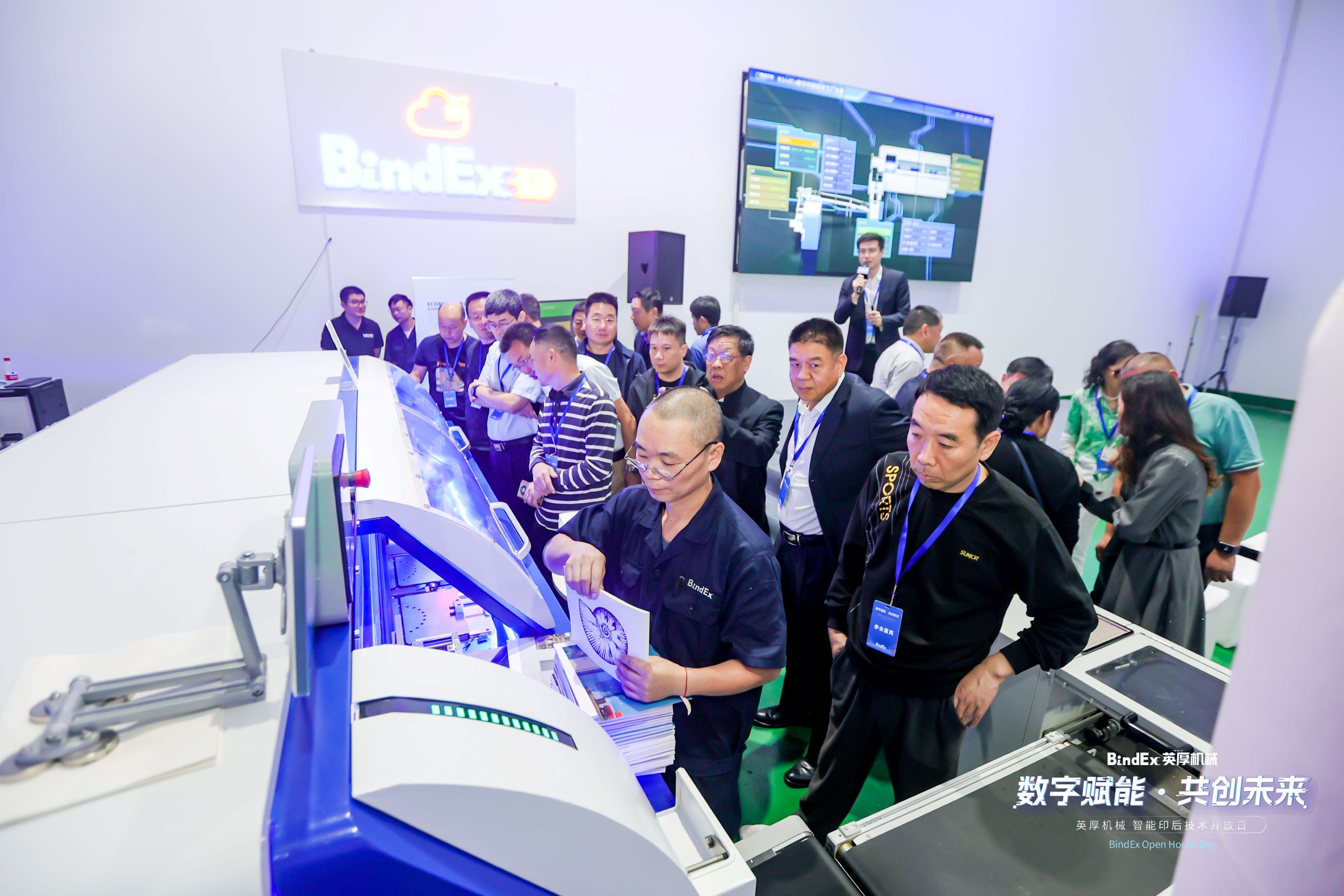

Subsequently, participants visited the ECOBINDER digital perfect binding line. It adopts a design with double bottom glue pots and a single-side glue pot, providing stronger adhesive permeability for more stable and robust end products. The book clamp can automatically adjust based on the results of automatic thickness measurement, saving setup time and improving post-press processing efficiency.

On-site observation of the Partex Interconnected Workshop Efficiency Monitoring System

The Partex Interconnected Intelligent IoT Management System utilizes IoT technology to network processing equipment during the printing process. It accurately records information such as machine tool status, processing time, and code execution, automatically collects data on standby reasons, spindle load, equipment vibration, energy consumption, and emissions, and monitors the production equipment and status in real-time. It also automatically analyzes existing data.

Partex Interconnected Intelligent IoT Management System real-time efficiency display

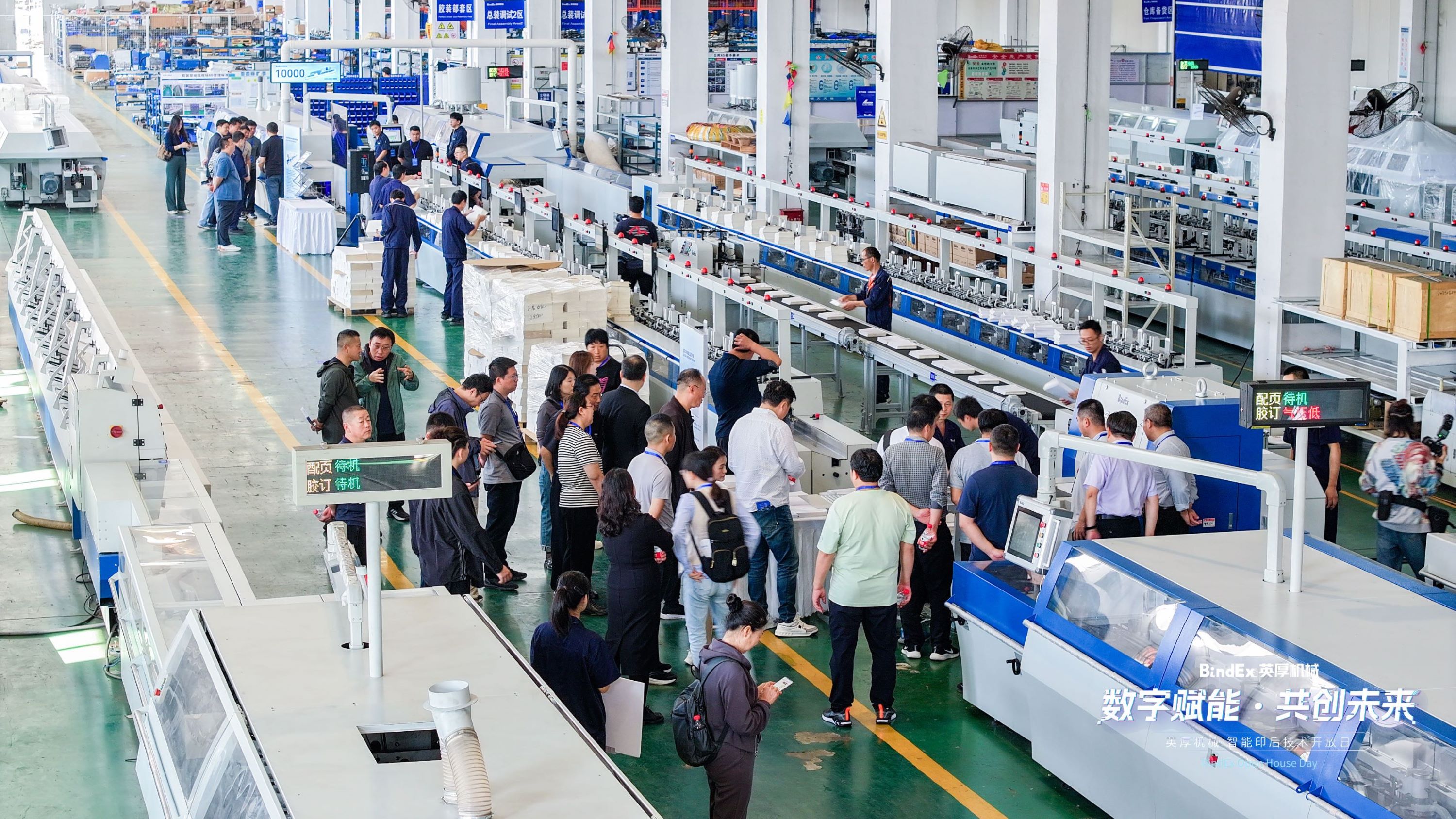

High-speed perfect binding line

At the same time, everyone visited the EXPLORER 12000e perfect binding line. This production line is equipped with an innovative whirlwind milling back function, ensuring a smooth spine and easily achieving adhesive binding for books and periodicals with cover lengths ranging from 140mm to 450mm and widths from 223mm to 635mm. It is widely used in textbooks and teaching materials, with a daily output of up to 200,000 copies.

Leveled-book intelligent adhesive binding production line

Later, participants together observed the Leveled-Book Intelligent Adhesive Binding Production Line, with a maximum speed of up to 6,000 copies/hour (leveled books) and 8,000 copies/hour (regular books). It is a highly intelligent device that can meet the requirements of various specifications and styles of leveled books and can also satisfy the demands of ordinary all-category adhesive-bound books with one-key setup. Everyone carefully examined the finished products produced by this production line and praised its performance.

On-site visit to the latest applications of intelligent factories

After the factory tour, the visiting group, led by relevant personnel, visited Mo Zhihua Printing. In the first-floor hall of Mo Zhihua Printing, the responsible person introduced the development history and main business of Mo Zhihua Printing. Emphasis was placed on the application of the BindEx Machinery intelligent factory screen in their enterprise. It not only enables real-time monitoring of production situations but also allows for production scheduling based on equipment operation conditions, greatly contributing to its rapid development.

During the Intelligent Post-Press Technology Open Day, the rapid development of BindEx Machinery in both hardware and software fields received recognition from industry builders and participants. The splendid appearance of BindEx Machinery at the 2023 All in Print China exhibition also foreshadows the limitless possibilities for the development of the printing industry. BindEx Machinery will continue to work hard in the intelligent post-press equipment industry, solidify hardware and software products, and look forward to creating more innovations and breakthroughs in the printing industry.