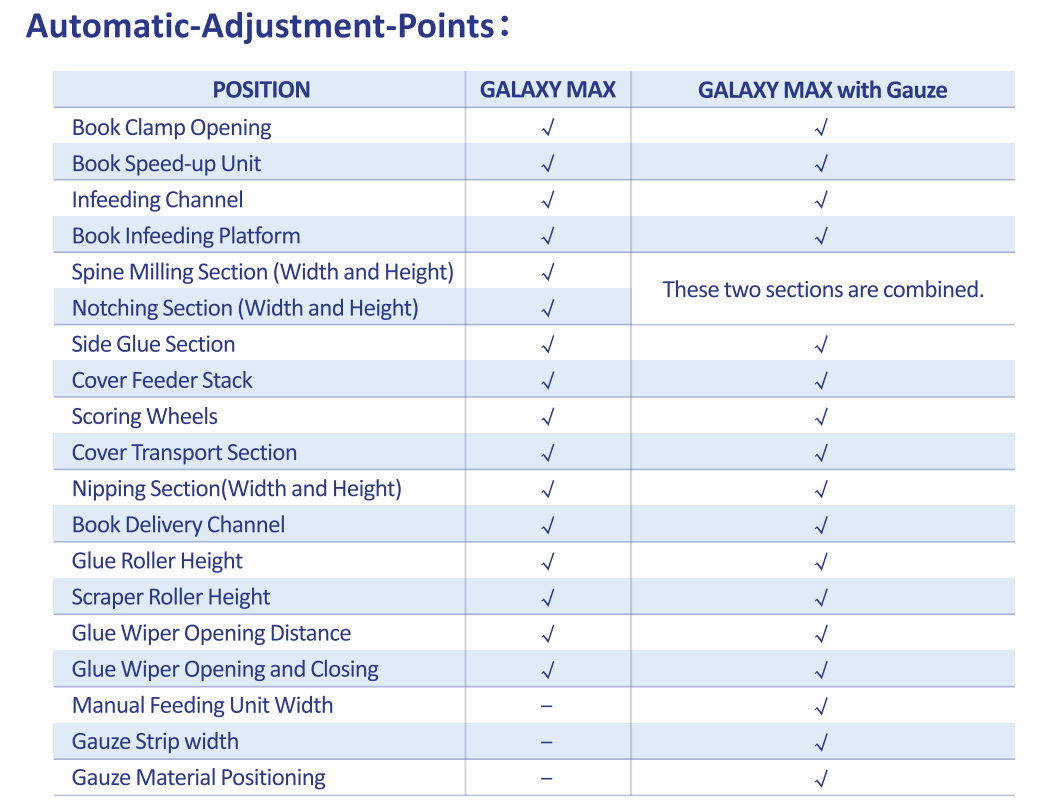

GALAXY MAX allows all adjustments to key positions to be done on the touch screen by means of servo motor control, an automatic book block infeeding mechanism is designed to replace the conventional manual book-feeding platform. The new design not only reduces labor intensity, but also allows the machine to integrate itself with book block preparation systems to form inline production.

Applying years of experiences and technologies from big binding lines, GALAXY MAX perfectly realized industrial book quality binding for digital printing/commercial printing/short run printing.

Technical Features

- Easy to use thanks to interactive user interface via touch screen.

- Industrial and heavy-duty design and frame to ensure professional book binding quality.

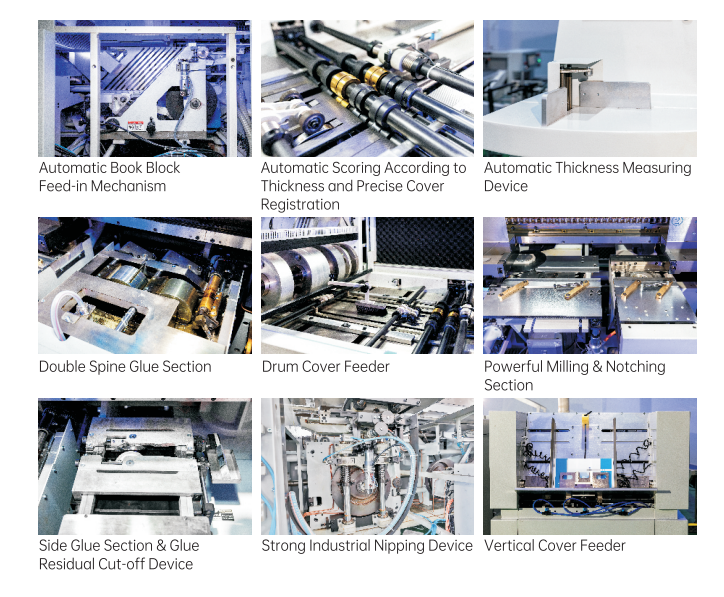

- Drum cover feeder realize non-stop continuous cover feeding; Reliable feeding for flapped covers; guides adjustments automatic according cover sizes.

- All book thickness related adjustments are made automatically within 8 minutes.

- Automatic book block infeeding mechanism is designed to replace the conventional manual book-feeding platform.

- Professional independent milling and notching section for superior spine preparation; Servo motor control of integrated notching and brush chip device.

- Movable spine-glue with double-rollers and side-gluing unit.

Glue unit with full servo control: Glue roller heights, scraper roller height adjustment automatic, Glue wiper opening and closing and timing controlled by servo motors .

- A movable glue premelting unit. Ensure uninterrupted supply of glue during production.

- Heavy duty double cam mechanism for superior spine nipping quality.

- Automatic book collecting section, to ensure high quality book spine formation.

Options

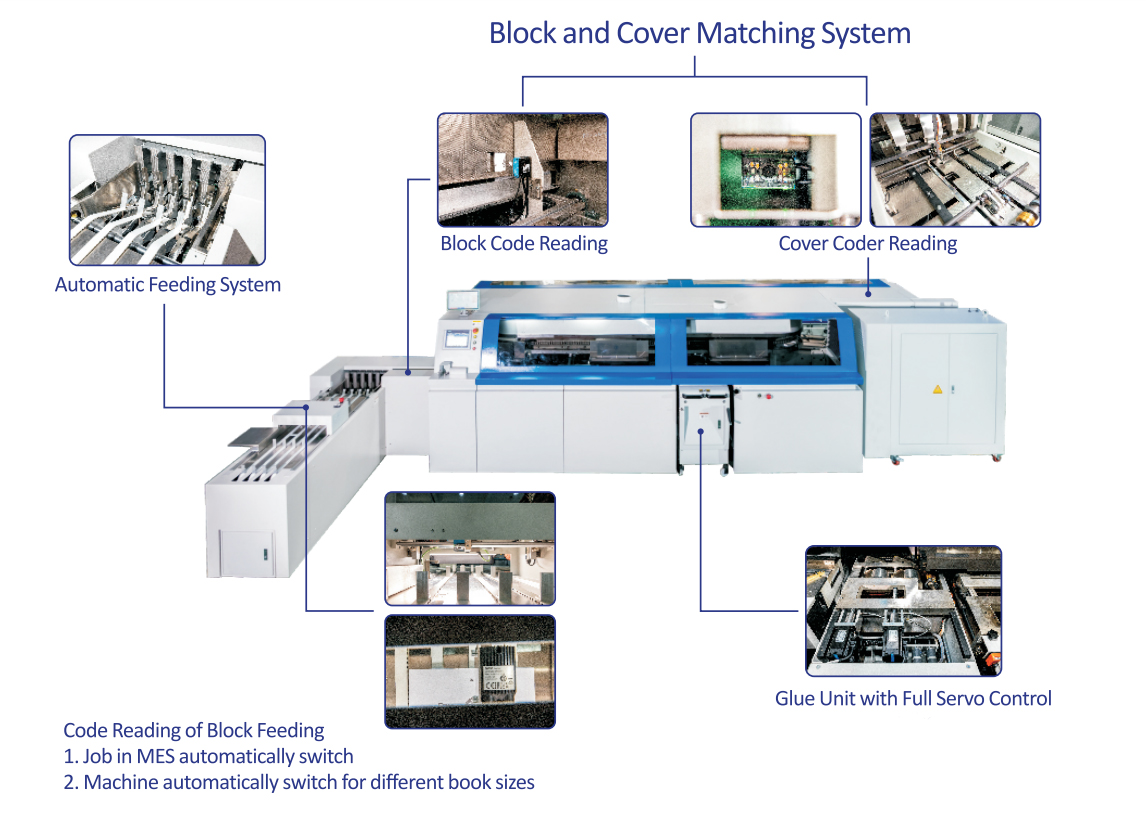

1. Book block and cover matching detection system

-Match the bar code on the cover and the block.

2. Automatic format change system by barcode/QRcode

-Through the recognition of the book block bar code by the reader, the book size is automatically obtained and the format is automatically changed.

3. BindEx Clound Digital Factory Solution

4. automatic feeding system for book blocks with digitally printed loose sheets

5. Connect with BOSSA50e or JAZZ 100e series three knife trimmer

6. Connect with PYGD450A or Y450e gathering machine

7. closed gluing system for PUR, automatic change between PUR and EVA book binding

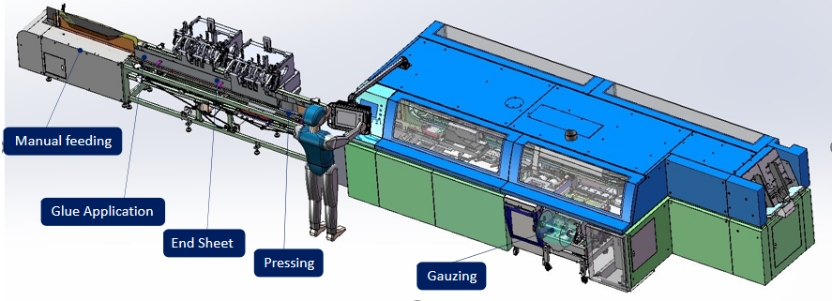

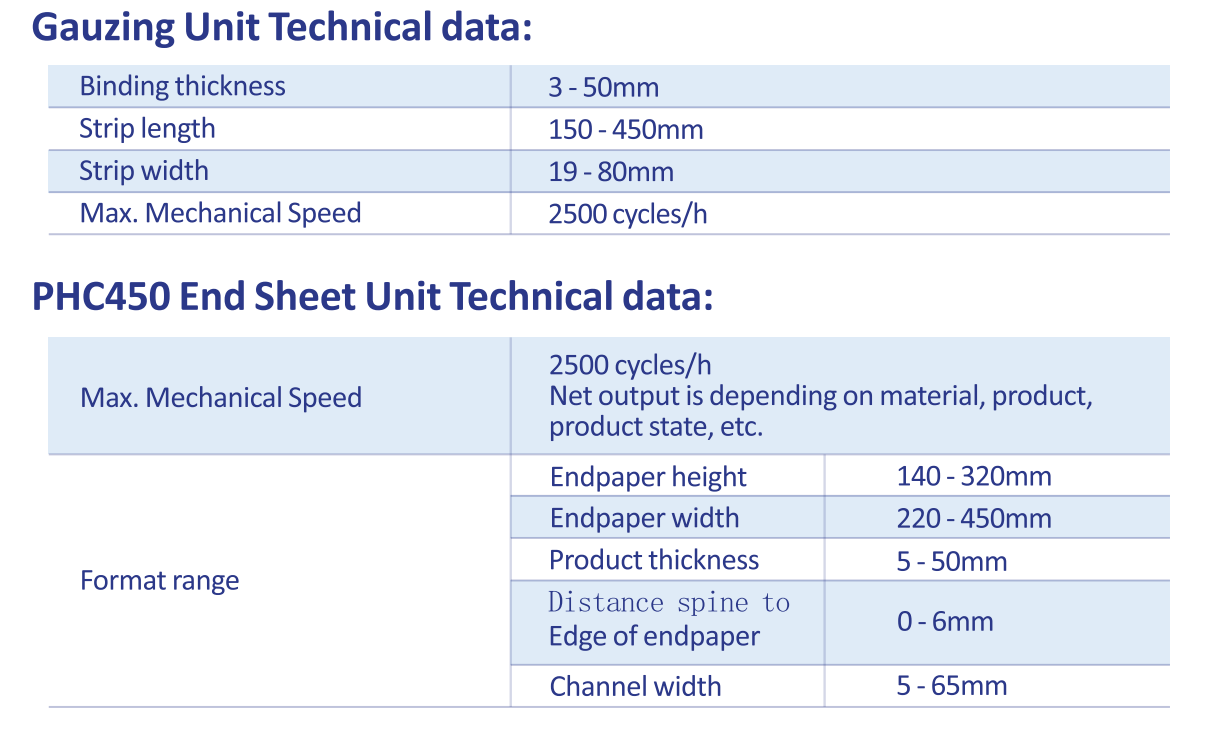

Gauzing Unit:

For application of gauzing material onto book blocks

- With setting of product thickness by motor

- Dynamic drive system for positioning of the gauze material

- Manual setting of the gauzing unit height for different gauzing materials or product hang-out

- Premium carbide knife as standard for long lifetime of the cutting knife

PHC450 End Sheet Unit:

For the application of endpapers

- Manual feeding unit (with option to connect book block feeder)

- Two rotary end sheet feeders in dynamic-drive technology

- Coldglue-nozzle-system with adjustments on glue heights

- Independent drive for transport chain

- Automatic width adjustments according to book thickness

- Independent drives for pressing wheels for optimal pressing quality

| Book clamp number | 6 |

| Max. Mechanical Speed | 2500 c/h |

| Max. Binding Size | 400mm×270mm |

| Min. Binding Size | 150mm×105mm |

| Max. Cover Size | 400mm×630mm |

| Min. Cover Size | 150mm×226mm |

| Binding thickness | 3mm-50mm |

| Main power | 24kw |

| Net weight | 6000kg |

| Overall dimensions (L×W×H) | 6750mm×2200mm×1500mm |