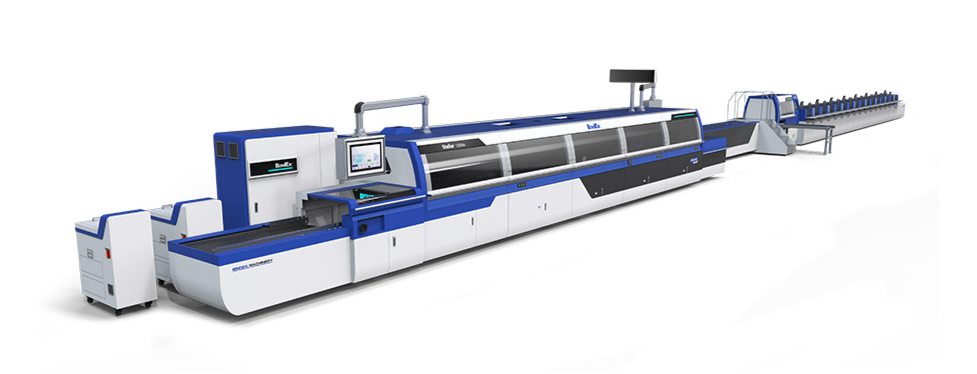

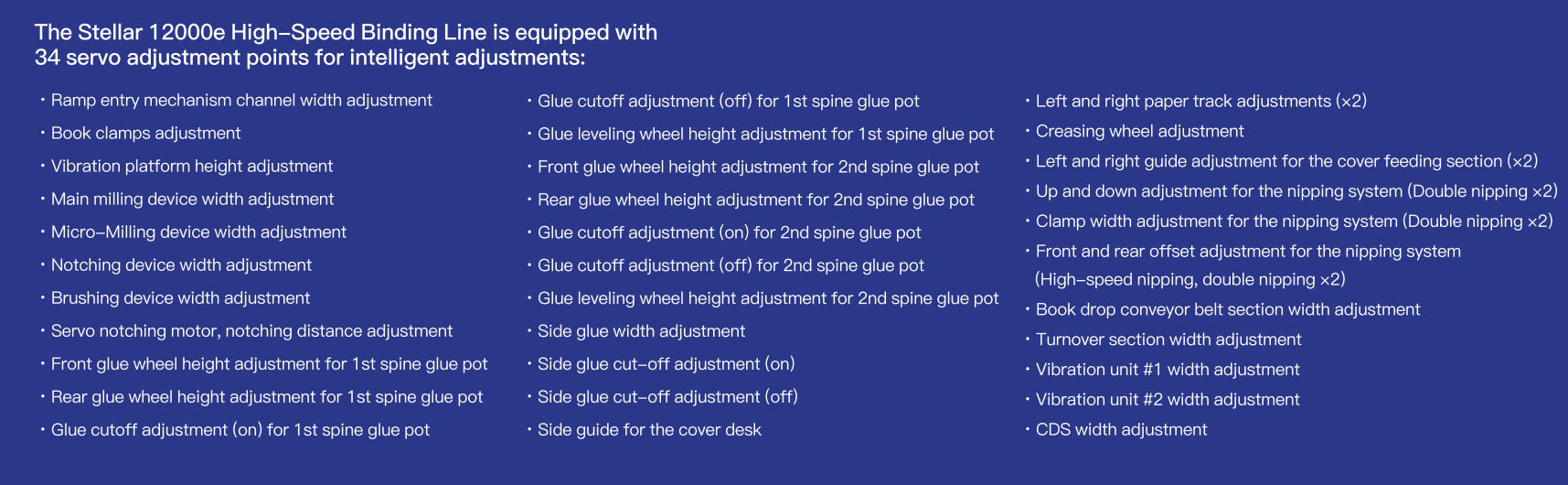

The Stellar 12000e is a newly developed, fully servo-driven perfect binding line by BindEx Machinery, engineered to meet the high-volume production demands of large-scale book and magazine manufacturers.With multiple servo-controlled adjustment points, it ensures precise setup, rapid changeovers, and high-efficiency production.

Product Characteristics:

Frame Structure

The base is integrally cast into a single piece

Multiple high-density steel wall panels are mounted on the base,connected by 50mm brackets to form the overall framework of the machine.

The part generating the most vibration—the milling device—is secured by two wall panels.

Features

The machine is heavy and robust, resistant to deformation and can be lifted as a whole.

During high-speed operation, it exhibits excellent stability with minimal vibration, ensuring the processing quality of books and magazines.

Book Block Preparation

The "Spine Milling - Notching - Brushing - Fine Milling" four-stage design effectively improves the accuracy of book block processing, ensuring high-quality book formation.

Spine Milling: Utilizes a high-power milling motor to ensure the flatness of the book spine after milling, facilitating subsequent spine gluing. Different milling knives (paper dust or paper strips) can be selected based on the client's factory waste disposal system.

Notching: The notching system uses a servo motor, with adjustable notch spacing. The speed of the notching motor automatically adjusts to match the machine's running speed, ensuring consistent notch spacing even at varying speeds.

Brushing: The chip deflector board features a fixed bottom brush and an adjustable side brush, which can be manually set based on book thickness. This prevents paper dust or flakes from spilling into the glue pot, ensuring clean glue application and better book quality.

Fine Milling: Adopts a reverse milling design. The secondary milling process removes paper debris from the grooves, ensuring even and full glue application on the spine for better bonding.

Full Servo Gluing System

Equipped with two movable dual-wheel spine glue units and one independently driven side gluing unit

Features

Four applications of spine glue ensure even distribution and reduce unglued areas on the spine.

The spine-side-spine glue pot layout ensures proper glue thickness.

The full servo spine glue system precisely controls the height of the glue wheels and the leveling bars through servo motors.

Servo motors control glue cutoff for both spine and side gluing, allowing for precise adjustments without stopping.

Cover Feeding System

Stream cover feeder to achieve cover loading without stopping the machine.

Includes: 1.5-meter cover conveyor, feeder system, and 4 standard creasing knives.

During operation, the cover guide can be fine-tuned, and both the front and rear cover feeding rails can be adjusted either collectively or individually.

Additional creasing knife sets can be added as needed to meet special requirements (e.g., for making flap cover books).

Equipped with a double-sheet detection system to monitor cover quantity, significantly reducing downtime and setup time, thus improving production efficiency.

Double Nipping Device

Uses double cam nipping platform technology.

During the nipping process, the platform can moves 100mm horizontally in sync with the book block, keeping it relatively stationary during pressing.

This stationary translation maximizes the time needed for spine shaping and glue curing.

The large distance between the two nipping devices ensures high-speed operation while maintaining the quality of spine formation.

Bindex Cloud Platform

Customers can optionally install the BindEx cloud platform based on their needs.

BindEx cloud platform can be integrated with mainstream ERP and MES systems to support the customer's digital printing workflow, providing full visibility, traceability, and analysis of equipment production data, as well as enabling remote commands and monitoring. This helps printing enterprises build smart workshops.

Connected to the company's Y15S high-speed gathering machine, achieving a speed of 12,000 books per hour through the 1:2 gathering function.

| Book Clamp Number | 28 |

| Binding length (mm) | 140-450 |

| Binding width (mm) | 130-300 |

| Cover length (mm) | 140-450 |

| Cover width (mm) | 263-635 |

| Binding thickness (mm) | 3-50 |

| Mechanical Speed (c/h) | 12000 |

| Main power (kw) | 55 |

| Net Weight (kg) | 10000 |

| Overall Dimensions:(L*W*H)(mm) | 13220×2100×2520 |