YOUR SOLUTION FOR THE DIGITAL THREAD SEWING OF BOOKS.

INTEGRATED THREAD SEWING SYSTEM WITH FEEDER FOR DIGITALLY PRINTED FOUR-SIDED SHEETS.

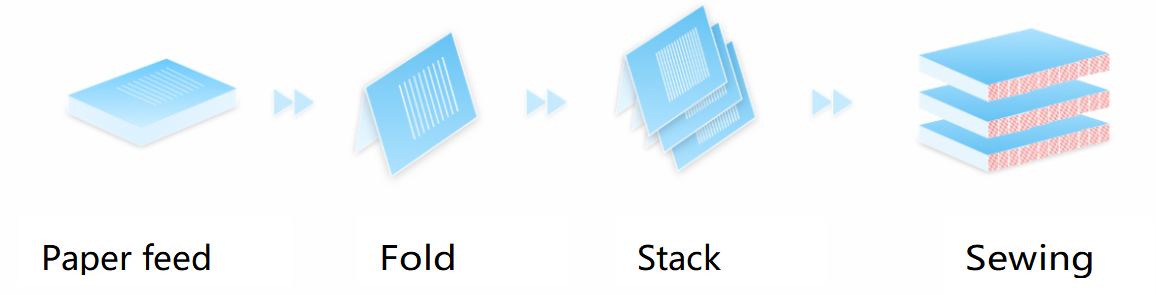

Your digitally printed and sequentially arranged four-sided sheets will be taken from a suction feeder, creased, folded and crossed in a number that you have previously defined, so as to make up the signature in a variable number of sheets 4, 8, 16, etc., for the same book.

The signatures are then automatically fed into the sewing machine for thread sewing, which is repeated until the book is completed.

At this point, the sewing machine performs an empty step and cuts the thread; it then starts again to automatically compose another volume.

MAIN FEATURES.

●PLC controlled machine;

●Encoder for phase management;

●Colour touch screen for data input for programming, machine management and displaying errors;

●Memorisation of repetitive work for quick start-up;

●Universal creaser for any paper grammage;

●Combined pump for suctioning the sheets from the feeder and blower for leafing the paper;

●Double or missing sheet check with ultrasonic sensor without any adjustments by stopping the machine during operation;

●Sequence control with black mark detection that you apply to a signature of your choice;

●Possibility to change the sequence to correct double, missing or jamming errors;

●Feeder with battery charger and self-aligning motorised suction head;

●Maximum speed 135 mt / min.

Digital Sewing Machine

| Min. sewing size | 150x120mm |

| Max. sewing size | 410x220mm |

| Max. loading height | 600mm |

| Paper weight | 55 - 170 gsm |

| Max. needle group | 10 |

| Needle interval | 20mm |

| Mechanical speed | 50-85 Signatures/min |

| Power | 5kw |

| Net weight | 1600kg |

| Overall dimensions(L*W*H) | 3647*2001*1588mm |